Cov Ntawv Iav Epoxy Rigid Laminated Sheets (EPGC sheets)

EPGC series Epoxy Iav Ntaub Rigid Laminated Sheet muaj cov ntaub iav woven impregnated nrog epoxy thermoseting resin, laminated nyob rau hauv qhov kub siab thiab siab siab. Cov ntaub iav woven yuav tsum tsis muaj alkali thiab kho los ntawm silane coupler. EPGC serial ntawv suav nrog EPGC201 (NMEMA G10), EPGC202 (NEMA FR4), EPGC203 (NEMA G11), EPGC204 (NEMA FR5), EPGC306 thiab EPGC308.

Cov ntawv EPGC (chav kawm thermal: B ~ H), tsim tawm raws li IEC60893-3-2. Cov ntawv no muaj lub zog zoo heev (qhov ceev ntawm lub xeev thermal tuaj yeem ncav cuag ntau dua 50%) nyob rau hauv qhov kub nruab nrab lossis lub xeev thermal, nrog rau cov khoom siv hluav taws xob ruaj khov (qhov kev tiv thaiv rwb thaiv tsev tom qab immersion ncav cuag 1012Ω) nyob rau hauv cov av noo siab. Thiab tseem muaj kev ua siab ntev voltage / withstand voltage siab dua (ntau dua 35kV), sib luag rau lamination. EPGC202, EPGC204 thiab EPGC306 kuj muaj cov khoom tiv taus hluav taws zoo heev. Cov ntawv kuj tau dhau qhov kuaj pom cov tshuaj lom thiab cov tshuaj phom sij (nrog RoHS Daim Ntawv Qhia).

Siv ua cov khoom siv rwb thaiv tsev hauv Class BH lub cev muaj zog hluav taws xob, cov khoom siv hluav taws xob, uas muaj qhov yuav tsum tau ua kom tsis txhob muaj hluav taws, lossis lwm yam kev siv.

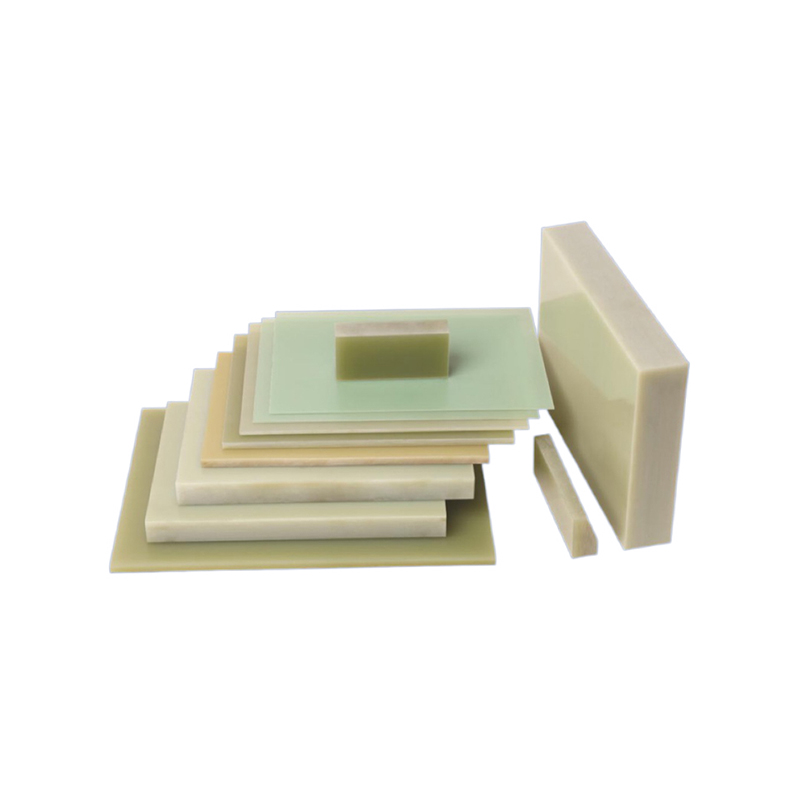

Muaj qhov tuab:0.30 hli ~ 200 hli

Muaj daim ntawv loj:

1500mm * 3000mm, 1220mm * 3000mm, 1020mm * 3000mm, 1020mm * 2440mm, 1220mm * 2440mm, 1500mm * 2440mm, 1000mm * 2000mm, 1200mm * 2000mm thiab lwm qhov ntau thiab tsawg sib tham.

Kev Faib Tawm Thiab Hom Epgc Sheets

| Lub npe ntaus ntawv | Daim Ntawv Thov & Nta | Chav kawm thermal | |||

| D&F | GB/IEC | NEMA | lwm tus | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Rau cov tshuab, cov khoom siv hluav taws xob thiab cov hluav taws xob. Nrog lub zog siab nyob rau hauv qhov kub nruab nrab, kev tiv thaiv arc zoo heev thiab PTI thiab CTI siab dua | Kub 130 ℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1, F881 | Zoo ib yam li EPGC201, muaj cov nplaim taws retardant tau hais. | Kub 130 ℃ |

| DF202A | --- | --- | --- | Zoo ib yam li DF202, tab sis muaj zog dua. | Kub 130 ℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Rau cov khoom siv kho tshuab, khoom siv hluav taws xob thiab cov hluav taws xob. Nrog lub zog siab tshaj plaws hauv qab qhov kub nruab nrab | F 155 ℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Zoo ib yam li DF203, muaj cov nplaim taws retardant. | F 155 ℃ |

| DF306 | EPGC306 | --- | DF336 | Zoo ib yam li DF203, muaj cov nplaim taws zoo heev, arc tsis kam thiab PTI siab dua. | F 155 ℃ |

| DF306A | --- | --- | --- | Zoo ib yam li DF306, tab sis muaj lub zog kho tshuab siab dua. | F 155 ℃ |

| DF308 | EPGC308 | --- | --- | Zoo ib yam li DF203, tab sis nrog kev ruaj khov thermal zoo dua. | Kub 180 ℃ |

Cov Kev Cai Txuj Ci

Qhov tsos

Qhov saum npoo ntawm daim ntawv yuav tsum tiaj tus thiab du, tsis muaj npuas cua, wrinkles lossis tawg thiab tsis muaj lwm yam me me xws li khawb, dents, thiab lwm yam. Ntug ntawm daim ntawv yuav tsum huv si thiab tsis muaj delamination thiab tawg. Cov xim yuav tsum sib xws, tab sis ob peb stains raug tso cai.

Nominal thickness thiab kam rau uaChav: hli

| Qhov tuab ntawm nominal | Kev hloov pauv | Niminal thickness | Kev hloov pauv |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Lus Cim: Rau cov ntawv uas tsis yog nominal thickness uas tsis teev nyob rau hauv lub Rooj no, qhov kev hloov pauv uas tso cai yuav tsum zoo ib yam li qhov ntawm qhov tuab dua tom ntej. | |||

Kev Khoov Deflection rau Cov NtawvChav: hli

| Qhov tuab | Kev khoov khoov |

| 3.0 ~ 6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 |

Kev ua khoom siv kho tshuab:

Cov ntawv yuav tsum tsis muaj kab nrib pleb thiab cov khoom seem thaum siv cov tshuab xws li sawing, drilling, lathing thiab milling.

Cov Khoom Siv Lub Cev, Cov Khoom Siv Kho Tshuab Thiab Cov Khoom Siv Dielectric

| Tsis yog. | Cov Khoom | Chav tsev | EPGC201 | EPGC202 | EPGC203 | ||||

| Tus nqi txheem | Tus nqi ib txwm muaj | Tus nqi txheem | Tus nqi ib txwm muaj | Tus nqi txheem | Tus nqi ib txwm muaj | ||||

| 1 | Kev nqus dej (2 hli ntawv) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Lub zog flexual | Nyob rau hauv ib txwm mob | MPa | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Ntev ntev) | 155 ℃ +/- 2 ℃ | --- | --- | --- | --- | ≥170 | 240 | ||

| 3 | Lub zog cuam tshuam, sib luag rau laminations (Charpy, notch) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Lub zog hluav taws xob, perpendicular rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃) | kV/hli | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Lub zog hluav taws xob, sib luag rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Dielectric dissipation factor (1MHz) | --- | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.021 | |

| 7 | Dielectric tas li (1MHz) | --- | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Arc tsis kam | s | --- | --- | --- | 182 | --- | 182 | |

| 9 | Kev tiv thaiv kev taug qab pov thawj (PTI) | V | --- | --- | --- | 600 | --- | 600 | |

| 10 | Kev tiv thaiv rwb thaiv tsev tom qab immersion hauv dej | MΩ | ≥5.0x104 | 2.1 x107 | ≥5.0x104 | 1.5 x106 | ≥5.0x104 | 1.1 x107 | |

| 11 | Kev kub hnyiab | Qib | --- | --- | V-0 | V-0 | --- | --- | |

| 12 | Kub Ntsuas (TI) | --- | ≥130 | ≥130 | ≥155 | ||||

| Tsis yog. | Cov Khoom | Chav tsev | EPGC204 | EPGC306 | EPGC308 | ||||

| Tus nqi txheem | Tus nqi ib txwm muaj | Tus nqi txheem | Tus nqi ib txwm muaj | Tus nqi txheem | Tus nqi ib txwm muaj | ||||

| 1 | Kev nqus dej (2 hli) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Lub zog flexual | Nyob rau hauv ib txwm mob | MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Ntev ntev) | 155 ℃ +/- 2 ℃ | ≥170 | 260 | ≥170 | 280 | --- | 270 | ||

| 3 | Lub zog cuam tshuam, sib luag rau laminations (Charpy, notch) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Lub zog hluav taws xob, perpendicular rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃) | kV/hli | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Lub zog hluav taws xob, sib luag rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Dielectric dissipation factor (1MHz) | --- | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Dielectric tas li (1MHz) | --- | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Arc tsis kam | s | --- | --- | --- | 182 | --- | --- | |

| 9 | Kev tiv thaiv kev taug qab pov thawj (PTI) | V | --- | --- | --- | 600 | --- | --- | |

| 10 | Kev tiv thaiv rwb thaiv tsev tom qab immersion hauv dej | MΩ | ≥5.0x104 | 3.8 x106 | ≥5.0x104 | 1.8 x107 | ≥5.0x104 | 7.1 x106 | |

| 11 | Kev kub hnyiab | Qib | V-0 | V-0 | V-0 | V-0 | --- | --- | |

| 12 | Kub Ntsuas (TI) | --- | ≥155 | ≥155 | ≥180 | ||||

Ntim Khoom Thiab Khaws Cia

Cov ntawv yuav tsum khaws cia rau qhov chaw uas kub tsis tshaj 40 ℃, thiab muab tso rau ntawm lub txaj pw uas siab li 50 hli lossis siab dua. Khaws cia kom deb ntawm hluav taws, cua sov (cov khoom siv cua sov) thiab tshav ntuj ncaj qha. Lub sijhawm khaws cia ntawm cov ntawv yog 18 lub hlis txij li hnub tawm hauv Hoobkas. Yog tias lub sijhawm khaws cia ntau tshaj 18 lub hlis, cov khoom kuj tseem siv tau tom qab kuaj xyuas kom tsim nyog.

Cov Lus Cim Thiab Cov Kev Ceev Faj Rau Daim Ntawv Thov

1 Kev siv tshuab yuav tsum ua raws li JB / Z141-1979,Cov txheej txheem machining ntawm cov khoom rwb thaiv tsev laminated, vim tias cov ntawv muaj qhov sib txawv ntawm tus cwj pwm los ntawm hlau.

2 Yuav tsum siv qhov ceev ceev thiab qhov tob me me thaum ua haujlwm vim tias cov ntawv tsis muaj zog thermal conductivity.

3 Kev siv tshuab thiab txiav cov khoom no yuav tso tawm ntau cov hmoov av thiab pa luam yeeb. Yuav tsum tau ua cov kev ntsuas kom zoo kom ntseeg tau tias cov hmoov av nyob hauv qhov txwv uas txaus siab thaum lub sijhawm ua haujlwm. Kev tso pa tawm hauv zos thiab siv cov ntaub npog ntsej muag plua plav/cov khoom me me uas tsim nyog.

4 Cov ntawv yuav raug dej noo tom qab raug tshuab, kev txheej txheej ntawm cov rwb thaiv tsev yog qhov pom zoo.

Cov Khoom Siv Tsim Khoom

Lub Pob Khoom Rau Cov Ntawv EPGC