D370 SMC Moulded rwb thaiv tsev ntawv

D370 SMC molded rwb thaiv tsev ntawv (D&F hom naj npawb: DF370) yog ib hom thermosetting nruj rwb thaiv tsev ntawv.Nws yog tsim los ntawm SMC hauv pwm nyob rau hauv qhov kub thiab txias.Nws yog nrog UL ntawv pov thawj thiab dhau qhov kev xeem ntawm REACH thiab RoHS, thiab lwm yam. Nws tseem hu ua SMC ntawv, SMC rwb thaiv tsev board, thiab lwm yam.

SMC yog ib hom ntawv molding compound uas muaj iav fiber reinforced nrog unsaturated polyester resin, ntim nrog hluav taws kub retardant thiab lwm yam khoom filling.

SMC cov nplooj ntawv muaj zog dua txhua yam, lub zog dielectric, nplaim taws zoo, taug qab tsis kam, arc tsis kam thiab siab dua tiv taus hluav taws xob, nrog rau kev nqus dej tsawg, ruaj khov qhov ntev thiab me me dabtsi yog khoov deflection.SMC nplooj ntawv yog siv los ua txhua yam ntawm insulating boards nyob rau hauv siab los yog tsawg voltage hloov zog.Nws kuj tseem siv tau los ua cov txheej txheem ntawm cov txheej txheem rwb thaiv tsev.

Thickness: 2.0mm ~ 60mm

Daim ntawv loj: 580mm * 850mm, 1000mm * 2000mm, 1300mm * 2000mm, 1500mm * 2000mm los yog lwm qhov ntau thiab tsawg

SMC

DMC

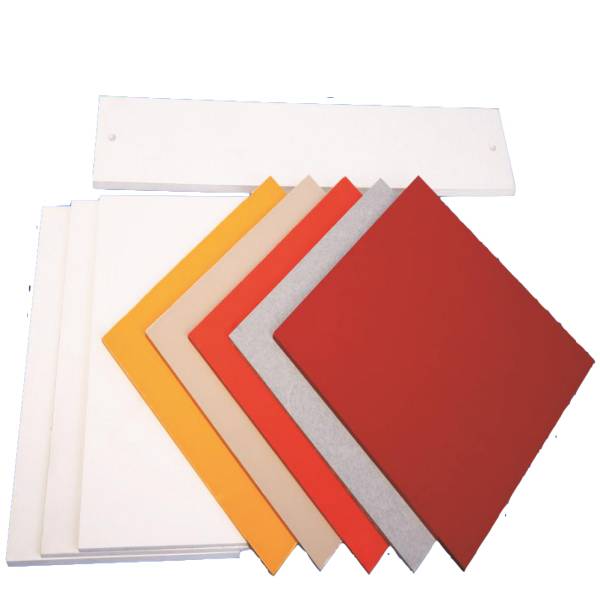

SMC nplooj ntawv Nrog cov xim sib txawv

SMC ntawv

Kev Xav Tau

Qhov tshwm sim

Nws nto yuav tsum tiaj tus thiab du, tsis muaj hlwv, dents thiab pom tseeb kev puas tsuaj.Cov xim ntawm nws saum npoo yuav tsum tsis sib xws, tsis muaj qhov pom tseeb pom fiber ntau.Dawb los ntawm pom tseeb paug, impurities thiab pom tseeb qhov.Dawb los ntawm delamination thiab crackles ntawm nws cov npoo.Yog tias muaj teeb meem ntawm qhov chaw ntawm cov khoom, lawv tuaj yeem patched.Cov hmoov tshauv superabundant yuav tsum tau ntxuav.

Cov bxaus deflectionUnit: mm

| Spec | Dimension ntawm cov duab | Nominal thickness S | Khoov deflection | Nominal thickness S | Khoov deflection | Nominal thickness S | Khoov deflection |

| D370 SMC daim ntawv | Ntev ntawm txhua sab ≤500 | 3 ≤S5 | ≤ 8 | 5 ≤S10 | ≤ 5 | ≥10 | ≤ 4 |

| Ntev ntawm ib sab | 3 ≤S5 | ≤12 | 5 ≤S10 | ≤ 8 | ≥10 | ≤ 6 | |

| 500 rau 1000 | |||||||

| Ntev ntawm ib sab ≥1000 | 3 ≤S5 | ≤ 20 | 5 ≤S10 | ≤ 15 | ≥10 | ≤10 |

Cov kev xav tau ntawm kev ua haujlwm

Lub cev, mechanical thiab hluav taws xob khoom rau SMC cov ntawv

| Cov khoom | Chav tsev | Txheem tus nqi | Yam nqi | Kev sim | ||

| Qhov ntom | g/cm3 | 1.65—1.95 Nws | 1.79 ib | GB/T1033.1-2008 | ||

| Barcol hardness | - | ≥ 55 | 60 | ASTM D 2583-07 Cov | ||

| Kev nqus dej, 3mm thickness | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Flexural zog, perpendicular rau laminations | Ntev ntev | MPa | ≥170

| 243 | GB/T1449-2005 | |

| Crosswise | ≥150 | 240 | ||||

| Impact Strength, parallel rau laminations (Charpy, unnotched) | KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Tensile zog | MPa | ≥55 | 143 | GB/T1447-2005 | ||

| Tensile elasticity modulus | MPa | ≥9000 | 1.48 x 104 | |||

| Molding shrinkage | % | - | 0.07 ib | ISO 2577: 2007 | ||

| Compressive zog (perpendicular rau laminations) | MPa | ≥150 | 195 | GB/T1448-2005 | ||

| Compressive modulus | MPa | - | 8300 ib | |||

| Thaum tshav kub kub deflection kub nyob rau hauv load (Tua ff1.8) | ℃ | ≥190 | ; 240 | GB/T1634.2-2004 | ||

| Coefficient ntawm liner thermal expansion (20 ℃ -40 ℃) | 10-6 / K | ≤18 | 16 | ISO 11359-2-1999 | ||

| Lub zog hluav taws xob (hauv 25 # transformer roj ntawm 23 ℃ +/- 2 ℃, luv-time test, Φ25mm / Φ75mm, cylindrical electrode) | KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| Kev tawg hluav taws xob (sib npaug rau laminations, hauv 25 # transformer roj ntawm 23 ℃ +/- 2 ℃, 20s step-by-step test, Φ130mm / Φ130mm, phaj electrode) | KV | ≥ 25 | > 100 | GB/T1408.1-2006 | ||

| Volume resistivity | Ω.m | ≥ 1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Nto resistivity | Ω | ≥ 1.0 x 1012 | 2.6 x 1012 | |||

| Relative permittivity (1MHz) | - | ≤ 4.8 | 4.54 ib | GB/T1409-2006 | ||

| Dielectric dissipation yam tseem ceeb (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Arc Resistance | s | ≥180 | 181 | GB/T1411-2002 | ||

| Taug qab tsis kam | CTI

| V | ≥600 | 600 Hla | GB/T1411-2002

| |

| PTI | ≥600 | 600 | ||||

| Rwb thaiv tsev tsis kam | Ntawm qhov xwm txheej | Ω | ≥ 1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Tom qab 24 teev hauv dej | ≥ 1.0 x 1012 | 2.5 x 1013 | ||||

| Flammability | Qib | V-0 | V-0 | UL94-2010 | ||

| Oxygen index | ℃ | ≥ 22 | 32.1 | GB / T2406.1 | ||

| Glow-wire test | ℃ | 850; ib | 960 ua | IEC 61800-5-1 | ||

Nrog voltage

| Nominal thickness (hli) | 3 | 4 | 5 x 6 | > 6 |

| Nrog voltage nyob rau hauv huab cua rau 1min KV | ≥ 25 | ≥33 | ≥42 | 48 |

Kev tshuaj xyuas, cim, ntim thiab cia

1. Txhua batch yuav tsum tau kuaj ua ntej xa.

2. Raws li qhov yuav tsum tau muaj ntawm cov neeg siv khoom, txoj kev sim ntawm kev tiv thaiv hluav taws xob yog sib tham raws li cov ntawv txheeb lossis cov duab.

3. Nws yog packed los ntawm cardboard lub thawv ntawm pallet.Nws qhov hnyav tsis ntau tshaj 500kg ib pallet.

4. Cov shee ts yuav tsum muab khaws cia rau hauv qhov chaw uas qhov kub tsis siab tshaj 40 ℃, thiab muab tso rau kab rov tav ntawm lub txaj nrog qhov siab ntawm 50mm lossis siab dua.Khaws kom deb ntawm hluav taws, cua sov (cov cuab yeej cua sov) thiab ncaj qha tshav ntuj.Lub neej cia ntawm nplooj ntawv yog 18 lub hlis txij li hnub tawm hauv lub Hoobkas.Yog tias lub sijhawm khaws cia ntev dua 18 lub hlis, cov khoom siv kuj tuaj yeem siv tom qab kuaj kom tsim nyog.

5. Lwm tus yuav tsum ua raws li cov kev cai ntawm GB/T1305-1985,General kev cai rau lub kev tshuaj xyuas, cim, ntim, kev thauj mus los thiab khaws cia cov khoom siv rwb thaiv tsev thermosetting.

Daim ntawv pov thawj