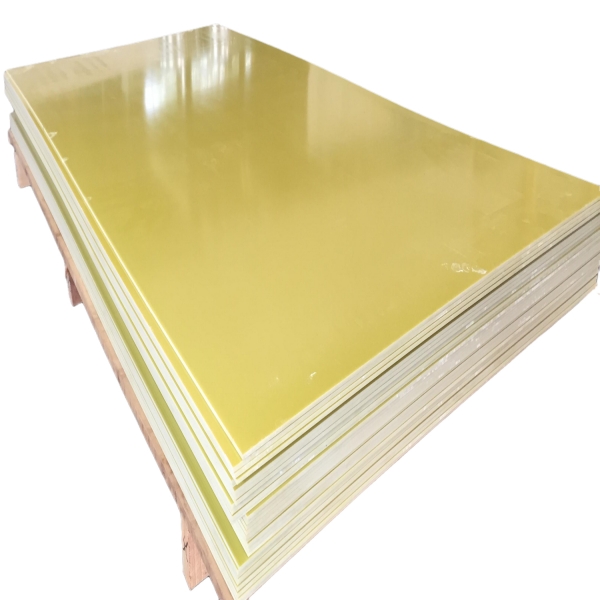

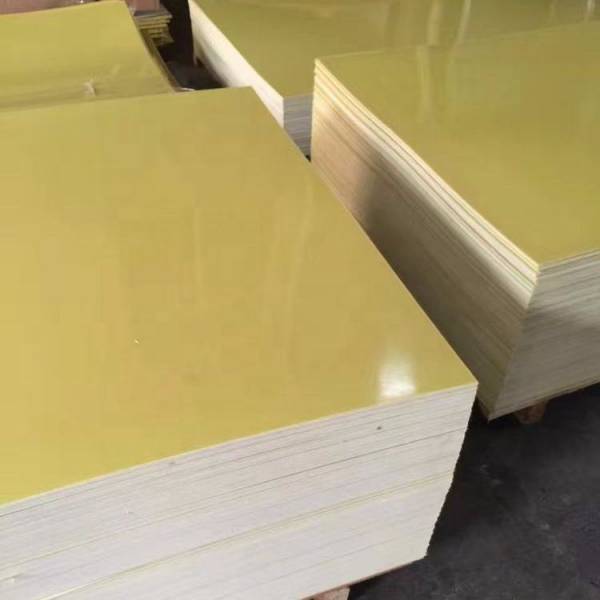

Cov Ntawv Iav Epoxy-Phenolic Zoo Zoo Laminated (3240)

Yuav kom txaus siab rau cov neeg siv khoom qhov kev txaus siab tshaj qhov xav tau, peb muaj peb pab pawg muaj zog los muab peb cov kev pabcuam zoo tshaj plaws uas suav nrog kev muag khoom, kev khwv tau nyiaj, kev tsim khoom, kev tsim khoom, kev tswj hwm zoo, kev ntim khoom, kev khaws cia thiab kev xa khoom rau Cov Ntawv Zoo Epoxy-Phenolic Iav Ntaub Laminated Sheets (3240), Tsis tas li ntawd, peb txoj kev lag luam ua raws li qhov zoo thiab tus nqi tiag tiag, thiab peb kuj muab cov kev pabcuam OEM zoo rau ntau lub npe nrov.

Yuav kom txaus siab rau cov neeg siv khoom qhov kev txaus siab uas ntau tshaj qhov xav tau, peb muaj peb pab pawg muaj zog los muab peb cov kev pabcuam zoo tshaj plaws uas suav nrog kev muag khoom, kev khwv tau nyiaj, kev tsim khoom, kev tsim khoom, kev tswj xyuas zoo, kev ntim khoom, kev khaws cia thiab kev xa khoom rauTuam Tshoj epoxy laminated ntawv thiab Epoxy-PhenolicPeb lub hauv paus ntsiab lus yog "kev ncaj ncees ua ntej, qhov zoo tshaj plaws". Tam sim no peb muaj kev ntseeg siab los muab kev pabcuam zoo heev thiab cov khoom zoo tagnrho rau koj. Peb vam tias peb tuaj yeem tsim kom muaj kev koom tes ua lag luam zoo nrog koj yav tom ntej!

Cov Kev Cai Txuj Ci

1.1Tsos:Qhov saum npoo ntawm daim ntawv yuav tsum tiaj tus thiab du, tsis muaj npuas cua, wrinkles lossis tawg thiab tsis muaj lwm yam me me xws li khawb, dents, thiab lwm yam. Ntug ntawm daim ntawv yuav tsum huv si thiab tsis muaj delaminations thiab tawg. Cov xim yuav tsum sib xws, tab sis ob peb staines raug tso cai.

1.2Qhov loj thiab qhov tso caikev kam rau siab

1.2.1 Dav thiab Ntev ntawm Cov Ntawv

| Dav & Ntev (hli) | Kev kam rau siab (hli) |

| >970 ~ 3000 | +/-25 |

1.2.2 Lub npe tuab & kev kam rau siab

| Lub npe tuab (hli) | Kev kam rau siab (hli) | Lub npe tuab (hli) | Kev kam rau siab (hli) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/-2.50 +/-2.80 |

| Lus Cim: Rau qhov tuab uas tsis yog nominal uas tsis tau teev nyob rau hauv lub rooj no, qhov sib txawv yuav zoo ib yam li qhov tuab dua tom ntej. | |||

1.3Kev khoov khoov

| Tuab (hli) | Kev khoov khoov | |

| 1000 hli (Tus kav ntev) (hli) | 500 hli (Tus kav ntev) (hli) | |

| 3.0 ~ 6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Kev ua khoom siv kho tshuab:cov ntawv yuav tsum tsis muaj kab nrib pleb, delaminations thiab scraps thaum xws li machining xws li sawing, drilling, lathing thiab milling yog siv.

1.5Cov khoom siv lub cev, tshuab thiab hluav taws xob

| Tsis yog. | Cov Khoom | Chav tsev | Tus nqi txheem | Tus nqi ib txwm muaj |

| 1 | Qhov Ceev | g/cm23 | 1.7~1.95 | 1.94 |

| 2 | Kev nqus dej (2 hli ntawv) | mg | ≤20 | 5.7 |

| 3 | Lub zog flexural, perpendicular rau laminations | MPa | ≥340 | 417 |

| 4 | Lub zog cuam tshuam (Charpy, notch) | kJ/m22 | ≥30 | 50 |

| 5 | Dielectric dissipation factor 50Hz | — | ≤5.5 | 4.48 |

| 6 | Dielectric tas mus li 50Hz | — | ≤0.04 | 0.02 |

| 7 | Kev tiv thaiv rwb thaiv tsev (Tom qab 24 teev hauv dej) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Lub zog dielectric, perpendicular rau laminationsin transformer roj ntawm 90 ℃ +/- 2 ℃, 1 hli ntawv | kV/hli | ≥14.2 | 16.8 |

| 9 | Lub zog tawg, sib luag rau laminationsin transformer roj ntawm 90 ℃ +/- 2 ℃ | kV | ≥35 | 38 |

Kev Ntim Khoom, Kev Thauj Mus Los thiab Kev Khaws Cia

Cov ntawv yuav tsum khaws cia rau qhov chaw uas kub tsis tshaj 40 ℃, thiab muab tso rau ntawm lub txaj pw uas siab li 50 hli lossis siab dua. Khaws cia kom deb ntawm hluav taws, cua sov (cov khoom siv cua sov) thiab tshav ntuj ncaj qha. Lub sijhawm khaws cia ntawm cov ntawv yog 18 lub hlis txij li hnub tawm hauv Hoobkas. Yog tias lub sijhawm khaws cia ntau tshaj 18 lub hlis, cov khoom kuj tseem siv tau tom qab kuaj xyuas kom tsim nyog.

Cov Lus Cim thiab Cov Kev Ceeb Toom rau Daim Ntawv Thov

Yuav tsum siv qhov ceev ceev thiab qhov tob me me g thaum ua haujlwm vim tias cov ntawv tsis muaj zog thermal conductivity.

Kev siv tshuab thiab txiav cov khoom no yuav tso tawm ntau cov hmoov av thiab pa luam yeeb. Yuav tsum ua raws li cov kev ntsuas kom zoo kom ntseeg tau tias cov hmoov av nyob hauv qhov txwv uas txaus siab thaum lub sijhawm ua haujlwm. Kev tso pa tawm hauv zos thiab siv cov ntaub npog ntsej muag plua plav/particle yog qhov pom zoo.

Cov ntawv yuav raug dej noo tom qab raug tshuab, pom zoo kom muaj txheej txheej rwb thaiv tsev.

Cov Khoom Siv Tsim Khoom

Lub Pob Rau Cov Ntawv Laminated

Yuav kom txaus siab rau cov neeg siv khoom qhov kev txaus siab tshaj qhov xav tau, peb muaj peb pab pawg muaj zog los muab peb cov kev pabcuam zoo tshaj plaws uas suav nrog kev muag khoom, kev khwv tau nyiaj, kev tsim khoom, kev tsim khoom, kev tswj hwm zoo, kev ntim khoom, kev khaws cia thiab kev xa khoom rau Cov Ntawv Zoo Epoxy-Phenolic Iav Ntaub Laminated Sheets (3240), Tsis tas li ntawd, peb txoj kev lag luam ua raws li qhov zoo thiab tus nqi tiag tiag, thiab peb kuj muab cov kev pabcuam OEM zoo rau ntau lub npe nrov.

Yuav kom txaus siab rau cov neeg siv khoom qhov kev txaus siab tshaj qhov xav tau, peb muaj peb pab pawg muaj zog los muab peb cov kev pabcuam zoo tshaj plaws uas suav nrog kev muag khoom, kev khwv tau nyiaj, kev tsim khoom, kev tsim khoom, kev tswj hwm zoo, kev ntim khoom, kev khaws cia thiab kev xa khoom rau Cov Ntawv Zoo Epoxy-Phenolic Iav Ntaub Laminated Sheets (3240), Tsis tas li ntawd, peb txoj kev lag luam ua raws li qhov zoo thiab tus nqi tiag tiag, thiab peb kuj muab cov kev pabcuam OEM zoo rau ntau lub npe nrov.

Zoo zooTuam Tshoj epoxy laminated ntawv thiab Epoxy-PhenolicPeb lub hauv paus ntsiab lus yog "kev ncaj ncees ua ntej, qhov zoo tshaj plaws". Tam sim no peb muaj kev ntseeg siab los muab kev pabcuam zoo heev thiab cov khoom zoo tagnrho rau koj. Peb vam tias peb tuaj yeem tsim kom muaj kev koom tes ua lag luam zoo nrog koj yav tom ntej!