Hoobkas Muag Khoom rau Tuam Tshoj Gpo3, Upgm203 Unsatured Polyester Iav Mat Phaj

Peb lub hom phiaj yog kom pom qhov zoo ntawm kev puas tsuaj hauv kev tsim khoom thiab muab kev txhawb nqa zoo tshaj plaws rau cov neeg yuav khoom hauv tsev thiab txawv teb chaws rau lub Hoobkas Muag Khoom rau Tuam Tshoj Gpo3, Upgm203 Unsatured Polyester Glass Mat Plate, Thaum peb tab tom txav mus tom ntej, peb saib xyuas peb cov khoom lag luam uas nthuav dav thiab txhim kho peb cov tuam txhab.

Peb lub hom phiaj yog kom pom cov khoom zoo thiab muaj txiaj ntsig zoo hauv kev tsim khoom thiab muab kev txhawb nqa zoo tshaj plaws rau cov neeg yuav khoom hauv tsev thiab txawv teb chaws tag nrho lub siabTuam Tshoj Upgm203 Iav Mat Phaj, upgm203Txij li thaum peb tsim los, peb pheej txhim kho peb cov khoom thiab kev pabcuam rau cov neeg siv khoom. Peb tau muab ntau yam khoom zoo rau koj ntawm cov nqi sib tw. Tsis tas li ntawd peb tuaj yeem tsim cov khoom sib txawv raws li koj cov qauv. Peb hais kom zoo thiab tus nqi tsim nyog. Tsuas yog qhov no, peb muab kev pabcuam OEM zoo tshaj plaws. Peb txais tos OEM xaj thiab cov neeg siv khoom thoob plaws ntiaj teb los koom tes nrog peb rau kev sib koom tes yav tom ntej.

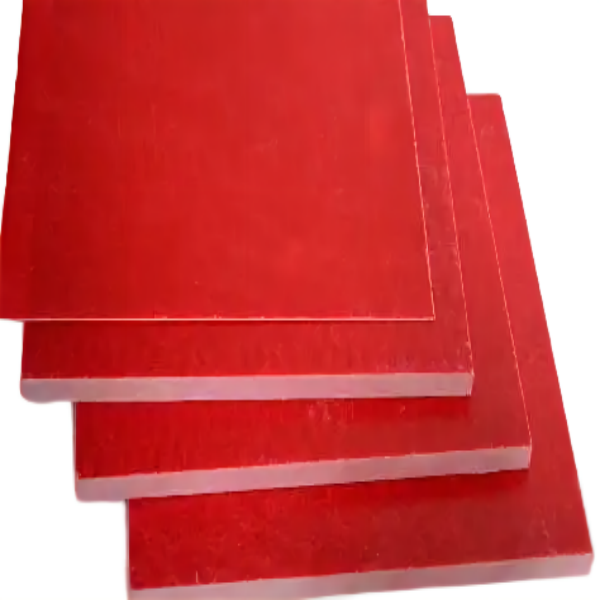

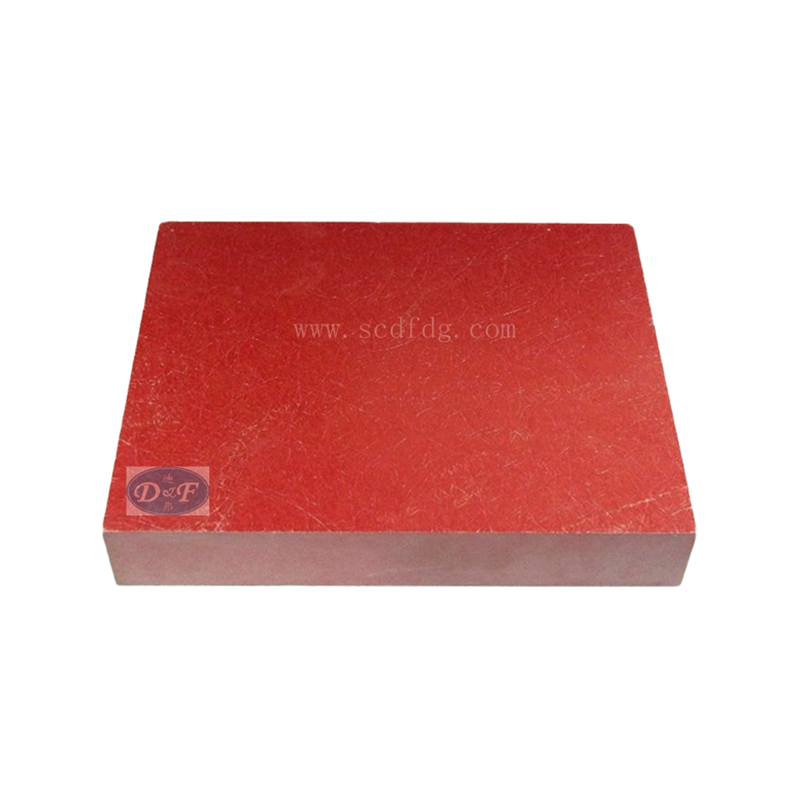

GPO-3 Moulded Sheet (tseem hu ua GPO3, UPGM203) muaj cov iav alkali-dawb lev impregnated thiab bonded nrog unsaturated polyester resin, thiab laminated nyob rau hauv kub siab thiab siab siab hauv pwm. Nws muaj machinability zoo, siab mechanical zog, zoo dielectric zog, zoo heev pov thawj taug qab tsis kam thiab arc tsis kam. Nws yog nrog UL daim ntawv pov thawj thiab dhau qhov kev xeem ntawm REACH thiab RoHS, thiab lwm yam. Nws tseem hu ua GPO-3 lossis GPO3 daim ntawv, GPO-3 lossis GPO3 rwb thaiv tsev board.

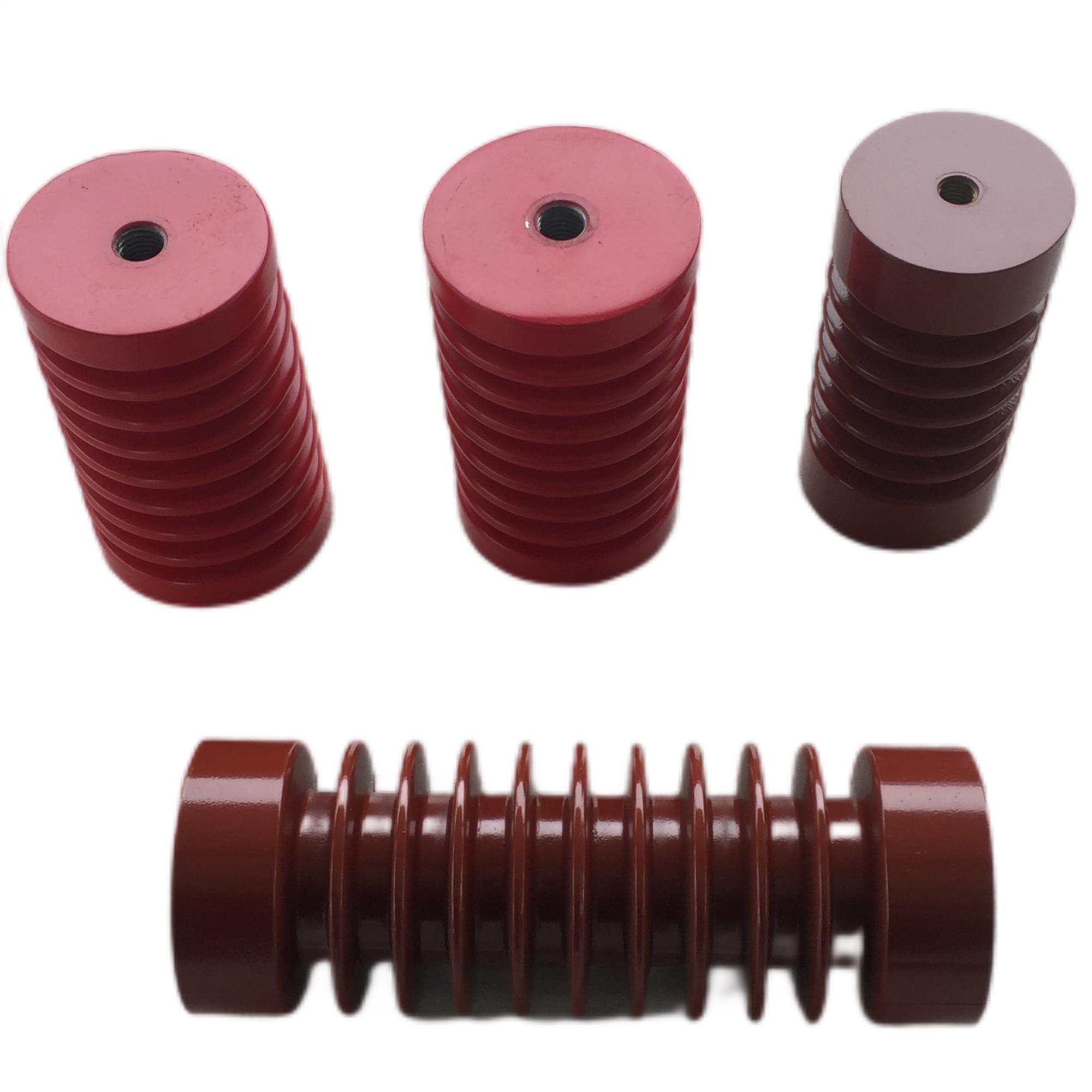

Nws siv tau rau kev ua cov khoom siv rwb thaiv tsev thiab cov khoom txhawb nqa lossis cov khoom siv hauv F-class electric motors, transformers, switch gears, circuit breakers thiab cov khoom siv hluav taws xob. UPGM tuaj yeem pwm ncaj qha rau hauv cov profiles sib txawv lossis cov khoom siv rwb thaiv tsev.

Qhov tuab ntau yam: 2 hli — 60 hli

Qhov loj ntawm daim ntawv: 1020mm * 2010mm, 1000mm * 2000mm, 1220mm * 2440mm thiab lwm yam tuab lossis / thiab qhov ntau thiab tsawg sib tham

Xim tseem ceebxim liab, dawb los yog lwm yam xim sib tham

Dhau li ntawm cov ntawv UPGM laminated, peb kuj tsim thiab muab cov ntawv EPGM 203, qhov loj ntawm daim ntawv zoo ib yam li cov ntawm GPO-3. Xim yog daj lossis ntsuab. Thov hu rau kuv kom paub ntau ntxiv.

Cov Kev Cai Txuj Ci

Qhov tsos

Nws qhov chaw yuav tsum tiaj tus thiab du, tsis muaj cov pob liab, cov qhov ntxhib los yog cov kab nrib pleb thiab tsis muaj lwm yam tsis zoo me me xws li khawb, qhov ntswj thiab cov xim tsis sib xws.

Ib txwm tqhov hnyav thiabkev kam rau siab

| Qhov Ntsuas Thickness (hli) | Kev kam rau siab (hli) | Qhov Ntsuas Thickness (hli) | Kev kam rau siab (hli) | |

| 0.8 | +/-0.23 | 12 | +/-0.90 | |

| 1.0 | +/-0.23 | 14 | +/-1.00 | |

| 2.0 | +/-0.30 | 16 | +/-1.10 | |

| 3.0 | +/-0.35 | 20 | +/-1.30 | |

| 4.0 | +/-0.40 | 25 | +/-1.40 | |

| 5.0 | +/-0.55 | 30 | +/-1.45 | |

| 6.0 | +/-0.60 | 40 | +/-1.55 | |

| 8.0 | +/-0.70 | 50 | +/-1.75 | |

| 10.0 | +/-0.80 | 60 | +/-1.90 | |

| Lus Cim: Rau cov ntawv uas tsis yog nominal thickness uas tsis teev nyob rau hauv lub rooj no, qhov kev hloov pauv uas tso cai yuav tsum zoo ib yam li qhov ntawm qhov tuab dua tom ntej. | ||||

Cov khoom siv lub cev, khoom siv kho tshuab thiab khoom siv hluav taws xob

| Cov Khoom | Chav tsev | Tus nqi txheem | Tus nqi ib txwm muaj | Txoj kev sim | ||

| Qhov Ceev | g/cm3 | 1.65~1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (Txoj kev A) | ||||||

| Kev nqus dej, 3 hli tuab | % | ≤ 0.2 | 0.16 | ASTM D790-03 | ||

| Lub zog flexural, perpendicular rau laminations (Lengthwise) | Nyob rau hauv ib txwm mob | MPa | ≥180 | 235 | ASTM D790-03 | |

| 130 ℃ +/- 2 ℃ | ≥100 | 144 | ||||

| Flexural modulus, perpendicular rau laminations (Lengthwise) | Nyob rau hauv ib txwm mob | MPa | - | 1.43 x 104 | ||

| 130 ℃ +/- 2 ℃ | - | 1.10 x 104 | ||||

| Lub zog flexural, perpendicular rau laminations (Lengthwise) | Ntev | MPa | ≥170 | 243 | GB/T 1449-2005 | |

| hla mus rau sab nraud | ≥150 | 240 | ||||

| Lub zog cuam tshuam, sib luag rau laminations | KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (Charpy, tsis muaj qhov) | ||||||

| Lub zog cuam tshuam, sib luag rau laminations | J/m | - | 921 | ASTM D256-06 | ||

| (Izod, notched) | ||||||

| Lub zog tensile | MPa | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Cov qauv elasticity ntawm lub zog tensile | MPa | ≥1.5 × 104 | 1.7 x 104 | |||

| Lub zog tensile, sib npaug rau laminations | Ntev | MPa | ≥55 | 165 | GB/T1447-2005 | |

| hla mus rau sab nraud | ≥55 | 168 | ||||

| Perpendicular rau laminations | MPa | - | 230 | ASTM D695-10 | ||

| Lub zog nias | ||||||

| Lub zog dielectric, perpendicular rau laminations (hauv 25 # transformer roj ntawm 90 ℃ +/- 2 ℃, kev sim luv luv, Φ25mm / Φ75mm cylindrical electrode) | KV/hli | ≥12 | 135 | IEC60243-1:2013 | ||

| Qhov hluav taws xob tawg, sib luag rau lanimations (hauv 25 # transformer roj ntawm 90 ℃ +/- 2 ℃, kev sim luv luv, Φ130mm / Φ130mm phaj electrode) | KV | ≥35 | > 100 | |||

| Kev tso cai txheeb ze (1MHz) | - | ≤ 4.8 | 4.54 | GB/T 1409-2006 | ||

| Qhov ntsuas dielectric dissipation (1MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Arc Tsis kam | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Kev taug qab tsis kam | CTI | V | ≥600 | CTI 600 | ||

| Kev hla hla | GB/T 4207-2012 | |||||

| PTI | ≥600 | PTI 600 | ||||

| Kev tiv thaiv rwb thaiv tsev | Nyob rau hauv ib txwm mob | Ω | ≥1.0 × 1013 | 5.4 x 1014 | GB/T 10064-2006 | |

| (Cov electrodes taper pin) | Tom qab 24 teev nyob hauv dej | ≥1.0 × 1012 | 2.5 x 1014 | |||

| Kev Kub Hnyiab (Txoj Kev Ntsug) | Qib | V-0 | V-0 | UL94-2013 | ||

| Hlau ci ntsa iab | - | - | GWIT: 960 / 3.0 | GB/T5169.13-2006 | ||

| Barcol hardness | - | ≥ 55 | 60 | ASTM D2583-07 | ||

Kev Tshuaj Xyuas, Cim, Ntim Khoom thiab Khaws Cia

1) Txhua pawg yuav tsum tau kuaj ua ntej xa tawm. Cov khoom tshuaj xyuas rau Kev Ntsuas Ib Txwm yuav tsum suav nrog Kab Lus 2.1, 2.2, thiab Khoom 1 thiab Khoom 3 ntawm Rooj 6 hauv Kab Lus 2.3. Cov khoom hauv Kab Lus 2.1, 2.2, yuav tsum tau kuaj ib qho zuj zus.

2) Cov ntawv yuav tsum khaws cia rau hauv qhov chaw uas qhov kub tsis siab tshaj 40 ℃, thiab muab tso rau ntawm lub txaj pw uas siab txog 50 hli lossis siab dua. Khaws cia kom deb ntawm hluav taws, cua sov (cov khoom siv cua sov) thiab tshav ntuj ncaj qha. Lub sijhawm khaws cia ntawm cov ntawv yog 18 lub hlis txij li hnub tawm hauv Hoobkas. Yog tias lub sijhawm khaws cia ntau tshaj 18 lub hlis, cov khoom kuj tseem siv tau tom qab kuaj xyuas kom tsim nyog.

Cov Lus Cim thiab Kev Ceev Faj rau Kev Siv thiab Kev Siv

1) Yuav tsum siv qhov ceev ceev thiab qhov tob me me ntawm kev txiav thaum ua haujlwm vim tias cov ntawv tsis muaj zog thermal conductivity.

2) Kev siv tshuab thiab txiav cov khoom no yuav tso tawm ntau cov hmoov av thiab pa luam yeeb. Yuav tsum tau ua cov kev ntsuas kom zoo kom ntseeg tau tias cov hmoov av nyob hauv qhov txwv uas txaus siab thaum lub sijhawm ua haujlwm. Kev tso pa tawm hauv zos thiab siv cov ntaub npog ntsej muag plua plav/cov khoom me me uas tsim nyog.

Daim Ntawv Pov Thawj

Peb lub hom phiaj yog kom pom qhov zoo ntawm kev puas tsuaj hauv kev tsim khoom thiab muab kev txhawb nqa zoo tshaj plaws rau cov neeg yuav khoom hauv tsev thiab txawv teb chaws rau lub Hoobkas Muag Khoom rau Tuam Tshoj Gpo3, Upgm203 Unsatured Polyester Glass Mat Plate, Thaum peb tab tom txav mus tom ntej, peb saib xyuas peb cov khoom lag luam uas nthuav dav thiab txhim kho peb cov tuam txhab.

Hoobkas Muag Khoom rauTuam Tshoj Upgm203 Iav Mat Phaj, Upgm203, Txij li thaum peb tsim, peb pheej txhim kho peb cov khoom thiab kev pabcuam rau cov neeg siv khoom. Peb tau muab ntau yam khoom zoo rau koj ntawm cov nqi sib tw. Tsis tas li ntawd peb tuaj yeem tsim cov khoom sib txawv raws li koj cov qauv. Peb hais kom zoo thiab tus nqi tsim nyog. Tsuas yog qhov no, peb muab kev pabcuam OEM zoo tshaj plaws. Peb txais tos OEM xaj thiab cov neeg siv khoom thoob plaws ntiaj teb los koom tes nrog peb rau kev sib koom tes yav tom ntej.