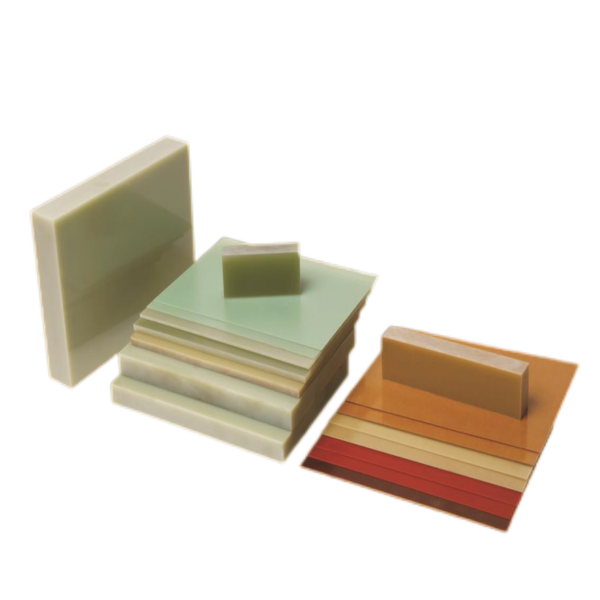

DF350A Hloov Kho Diphenyl Ether Iav Ntaub Rigid Laminated daim ntawv

DF350Amuaj cov ntaub iav woven impregnated nrog cov diphenyl ether thermosetting resin hloov kho, laminated nyob rau hauv kub siab thiab siab. Cov ntaub iav woven yuav tsum tsis muaj alkali thiab kho los ntawm KH560.

DF350A muaj kev tiv thaiv cua sov zoo, cov khoom siv kho tshuab thiab dielectric zoo heev, tsim nyog rau kev siv hauv H-chav kawm hluav taws xob lossis cov khoom siv hluav taws xob ua cov khoom siv rwb thaiv tsev lossis cov khoom siv. Tshwj xeeb tshaj yog siv rau hauv cov hluav taws xob lossis cov khoom siv hluav taws xob uas xav tau kev ua haujlwm siab dua hauv qab kev ntxhov siab thermal.

Muaj qhov tuab:0.5 hli ~ 200 hli

Muaj daim ntawv loj:

1500mm * 3000mm, 1220mm * 3000mm, 1020mm * 2040mm, 1220mm * 2440mm, 1000mm * 2000mm thiab lwm qhov ntau thiab tsawg sib tham.

Lub Nominal Thickness Thiab Kev Tso Cai Rau Kev Ua Siab Ntev (hli)

| Qhov tuab ntawm nominal | Kev hloov pauv | Qhov tuab ntawm nominal | Kev hloov pauv | Qhov tuab ntawm nominal | Kev hloov pauv |

| 0.5 | +/-0.15 | 3 | +/-0.37 | 16 | +/-1.12 |

| 0.6 | +/-0.15 | 4 | +/-0.45 | 20 | +/-1.30 |

| 0.8 | +/-0.18 | 5 | +/-0.52 | 25 | +/-1.50 |

| 1 | +/-0.18 | 6 | +/-0.60 | 30 | +/-1.70 |

| 1.2 | +/-0.21 | 8 | +/-0.72 | 35 | +/-1.95 |

| 1.5 | +/-0.25 | 10 | +/-0.94 | 40 | +/-2.10 |

| 2 | +/-0.30 | 12 | +/-0.94 | 45 | +/-2.45 |

| 2.5 | +/-0.33 | 14 | +/-1.02 | 50 | +/-2.60 |

Kev khoov Deflection (hli)

| Qhov tuab | Kev khoov khoov | |

| 1000 (Tus kav ntev) | 500 (Tus kav ntev) | |

| 3.0 ~ 6.0 | ≤10 | ≤2.5 |

| 6.1 ~ 8.0 | ≤8 | ≤2.0 |

| >8.0 | ≤6 | ≤1.5 |

Cov Khoom Siv Lub Cev, Cov Khoom Siv Kho Tshuab Thiab Cov Khoom Siv Dielectric

| Tsis yog. | Cov Khoom | Chav tsev | Tus nqi txheem | Tus nqi ib txwm muaj | ||

| 1 | Qhov Ceev | g/cm3 | 1.70~1.95 | 1.9 | ||

| 2 | Lub zog flexural, perpendicular rau laminations (Lengthwise) | Nyob rau hauv ib txwm mob | MPa | ≥400 | 540 | |

| 180 ℃ +/- 2 ℃ | ≥200 | 400 | ||||

| 3 | Lub zog cuam tshuam (Charpy, notch, lengthwise) | kJ/m2 | ≥37 | 50 | ||

| 4 | Lub zog nplaum/kev sib txuas | N | ≥5000 | 6900 | ||

| 5 | Kev nqus dej | mg | Saib lub rooj tom ntej | 11.8 | ||

| 6 | Kev tiv thaiv rwb thaiv tsev, sib luag rau laminations | Nyob rau hauv ib txwm mob | MΩ | ≥1.0 x 106 | 5.3 x 107 | |

| Tom qab 24 teev nyob hauv dej | ≥1.0 x 102 | 3.8 x 104 | ||||

| 7 | Dielectric dissipation factor 1MHz | -- | ≤0.05 | 1.03 x 10-2 | ||

| 8 | Dielectric tas mus li 1MHz | -- | ≤5.5 | 4.7 | ||

| 9 | Lub zog tawg, sib luag rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃) | kV | ≥30 | 35 | ||

| 10 | Lub zog dielectric, perpendicular rau laminations (hauv roj transformer ntawm 90 ℃ +/- 2 ℃), 2 hli ntawv | MV/m | ≥11.8 | 18 | ||

Kev Nqus Dej

| Qhov nruab nrab tuab ntawm cov qauv kuaj (hli) | Kev nqus dej (mg) | Qhov nruab nrab tuab ntawm cov qauv kuaj (hli) | Kev nqus dej (mg) | Qhov nruab nrab tuab ntawm cov qauv kuaj (hli) | Kev nqus dej (mg) |

| 0.5 | ≤17 | 2.5 | ≤21 | 12 | ≤38 |

| 0.8 | ≤18 | 3.0 | ≤22 | 16 | ≤46 |

| 1.0 | ≤18 | 5.0 | ≤25 | 20 | ≤52 |

| 1.6 | ≤19 | 8.0 | ≤31 | 25 | ≤61 |

| 2.0 | ≤20 | 10 | ≤34 | Saib Cov Lus Cim 2 | ≤73 |

| Cov Lus Cim:1) Yog tias qhov nruab nrab ntawm qhov tuab uas ntsuas tau yog nyob nruab nrab ntawm ob qhov tuab uas tau hais hauv daim ntawv no, cov nqi yuav raug nrhiav los ntawm kev sib xyaw. Yog tias qhov nruab nrab ntawm qhov tuab uas ntsuas tau tsawg dua 0.5 hli, cov nqi yuav tsis tshaj 17 mg. Yog tias qhov nruab nrab ntawm qhov tuab uas ntsuas tau yog tshaj 25 hli, tus nqi yuav tsis tshaj 61 mg. 2) Yog tias qhov tuab nominal ntau tshaj 25 hli, nws yuav tsum tau tshuab kom txog 22.5 hli ntawm ib sab. Sab uas tshuab yuav tsum du. | |||||

Ntim Khoom Thiab Khaws Cia

Cov ntawv yuav tsum khaws cia rau hauv qhov chaw uas qhov kub tsis siab tshaj 40 ℃, thiab muab tso rau ntawm lub txaj pw uas siab txog 50 hli lossis siab dua.

Khaws cia kom deb ntawm hluav taws, cua sov (cov khoom siv cua sov) thiab tshav ntuj ncaj qha. Lub sijhawm khaws cia ntawm cov ntawv yog 18 lub hlis txij li hnub tawm hauv Hoobkas. Yog tias lub sijhawm khaws cia yog ntau tshaj 18 lub hlis, cov khoom kuj tseem siv tau tom qab kuaj xyuas kom tsim nyog.

Cov Lus Cim thiab Cov Kev Ceeb Toom rau Daim Ntawv Thov

Yuav tsum siv qhov ceev ceev thiab qhov tob me me thaum ua haujlwm vim tias cov ntawv tsis muaj zog thermal conductivity.

Kev siv tshuab thiab txiav cov khoom no yuav tso tawm ntau cov hmoov av thiab pa luam yeeb. Yuav tsum ua raws li cov kev ntsuas kom zoo kom ntseeg tau tias cov hmoov av nyob hauv qhov txwv uas txaus siab thaum lub sijhawm ua haujlwm. Kev tso pa tawm hauv zos thiab siv cov ntaub npog ntsej muag plua plav/cov khoom me me uas tsim nyog.

Cov ntawv yuav raug dej noo tom qab raug tshuab, pom zoo kom muaj txheej txheej rwb thaiv tsev.