6643 F-chav kawm DMD (DMD100) daim ntawv rwb thaiv tsev yooj ywm

6643 Cov yeeb yaj kiab Polyester hloov kho / polyester tsis-woven flexible laminate yog ib hom ntawm peb-txheej 100% epoxy resin saturated flexible composite insulation ntawv uas txhua sab ntawm polyester zaj duab xis (M) yog bonded nrog ib txheej ntawm polyester tsis-woven ntaub (D), ces coated nrog F-chav kawm hluav taws xob insulating resin. 6643 flexible hluav taws xob rwb thaiv tsev ntawv yog siv ua qhov rwb thaiv tsev, interphase rwb thaiv tsev thiab liner rwb thaiv tsev hauv F chav kawm hluav taws xob motors, tshwj xeeb tshaj yog haum rau mechanized ntxig qhov txheej txheem. 6643 dhau SGS xeem rau kev kuaj pom tshuaj lom thiab tshuaj txaus ntshai. Nws tseem hu ua F chav kawm DMD, DMD100, DMD-100 hluav taws xob rwb thaiv tsev khoom siv rau hluav taws xob motors.

Cov yam ntxwv ntawm cov khoom

Nrog cov tshuaj tiv thaiv kub-resistant uas encapsulates sab hauv polyester zaj duab xis & nplaum, yog li 6643 muaj cov khoom tiv thaiv kub zoo heev, cov khoom siv kho tshuab zoo heev, cov khoom hluav taws xob zoo heev thiab kev tiv thaiv thermal siab dua.

Cov ntawv thov

Nrog cov tshuaj pleev xim uas tiv taus cua sov, nws qhov chaw du thiab zoo dua. Nws tsim nyog rau kev siv tshuab ntxig qhov.

6643 yog siv rau kev rwb thaiv tsev qhov, kev rwb thaiv tsev interphase thiab kev rwb thaiv tsev liner hauv F chav kawm hluav taws xob motors, tshwj xeeb tshaj yog haum rau cov txheej txheem ntxig tshuab.

Cov Lus Qhia Txog Kev Muab Khoom

Qhov dav nominal: 1000 hli.

Qhov hnyav nominal: 50+/-5kg / Yob. 100+/-10kg / yob, 200+/-10kg / yob

Cov splices yuav tsum tsis pub ntau tshaj 3 hauv ib yob.

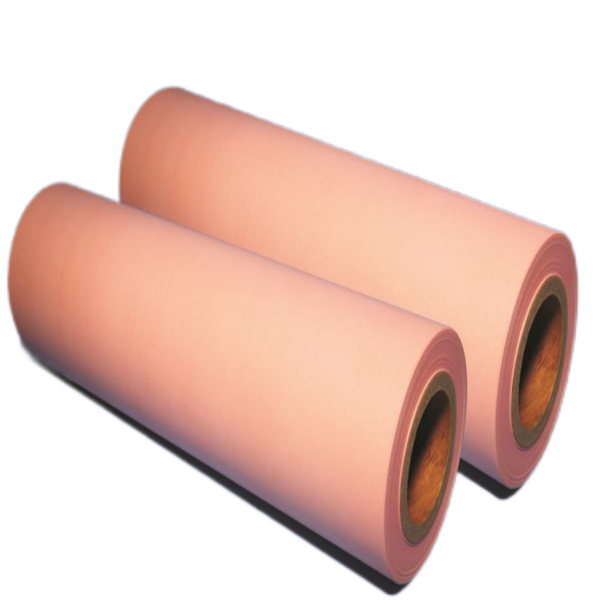

Xim: dawb, xiav, liab dawb los yog nrog D&F luam tawm logo.

Cov Kev Cai Ua Tau Zoo

Cov nqi txheem rau 6643 tau qhia nyob rau hauv Rooj 1 thiab cov nqi ib txwm muaj tau qhia nyob rau hauv Rooj 2.

Rooj 1: Cov nqi ua tau zoo rau 6643 DMD 100 daim ntawv rwb thaiv tsev yooj ywm

| Tsis yog. | Cov Khoom | Chav tsev | Cov nqi ua tau zoo ib txwm muaj | ||||||||||||||

| 1 | Cov qauv | mil | 2/2/2 | 2/3/2 | 2/4/2 | 3/3/3 | 2/5/2 | 2/6/2 | 3/5/3 | 2-7.5-2 | 3-7.5-3 | 2002/10/2 | 2003/10/3 | 2-14-2 | 3-14-3 | ||

| 2 | Qhov tuab ntawm nominal | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.23 | 0.25 | 0.28 | 0.3 | 0.35 | 0.36 | 0.4 | 0.45 | 0.5 | ||

| 3 | Kev kam rau siab tuab | mm | ±0.020 | ±0.025 | ±0.030 | ±0.030 | ±0.030 | ±0.030 | ±0.030 | ±0.035 | ±0.040 | ±0.040 | ±0.040 | ±0.045 | ±0.050 | ||

| 4 | PET zaj duab xis thickness | mm | 0.05 | 0.075 | 0.1 | 0.075 | 0.125 | 0.15 | 0.125 | 0.188 | 0.188 | 0.25 | 0.25 | 0.35 | 0.35 | ||

| 5 | Grammage | g/m2 | 160 | 210 | 245 | 255 | 265 | 310 | 325 | 360 | 400 | 445 | 505 | 580 | 640 | ||

| 6 | Lub zog tensile | MD | Tsis tau tais | N/10 hli | ≥90 | ≥110 | ≥130 | ≥120 | ≥150 | ≥170 | ≥170 | ≥200 | ≥220 | ≥260 | ≥300 | ≥330 | ≥360 |

| Tom qab tais | ≥80 | ≥100 | ≥110 | ≥105 | ≥120 | ≥140 | ≥150 | ≥180 | ≥200 | ≥220 | ≥240 | ≥280 | ≥300 | ||||

| TD | Tsis tau tais | ≥80 | ≥100 | ≥110 | ≥105 | ≥120 | ≥140 | ≥150 | ≥180 | ≥200 | ≥220 | ≥240 | ≥280 | ≥300 | |||

| Tom qab tais | ≥70 | ≥80 | ≥100 | ≥95 | ≥110 | ≥130 | ≥130 | ≥150 | ≥170 | ≥200 | ≥220 | ≥260 | ≥280 | ||||

| 7 | Lub zog tawg | Chav sov. | kV | ≥7.0 | ≥8.0 | ≥9.0 | ≥8.0 | ≥11.0 | ≥12.0 | ≥11.0 | ≥13.0 | ≥15.0 | ≥17.0 | ≥18.0 | ≥20.0 | ≥22.0 | |

| 8 | Kev cuam tshuam ntawm cua sov 180 ℃ +/- 2 ℃, 10 feeb | - | Tsis muaj delamination, tsis muaj npuas, tsis muaj nplaum ntws. | ||||||||||||||

| Lus Cim*: Cov nqi Grammage tsuas yog siv rau kev siv xwb. Nws kuj tseem nyob ntawm tus neeg siv qhov kev xav tau tshwj xeeb yog tias siv tau. | |||||||||||||||||

Rooj 2 Feem ntauCov nqi ua tau zoo rau 6643 DMD 100 daim ntawv rwb thaiv tsev yooj ywm

| Tsis yog. | Cov Khoom | Chav tsev | Cov nqi ua tau zoo ib txwm muaj | ||||||||||||||

| 1 | Cov qauv | mil | 2/2/2 | 2/3/2 | 2/4/2 | 3/3/3 | 2/5/2 | 2/6/2 | 3/5/3 | 2-7.5-2 | 3-7.5-3 | 2002/10/2 | 2003/10/3 | 2-14-2 | 3-14-3 | ||

| 2 | Qhov tuab ntawm nominal | mm | 0.16 | 0.18 | 0.21 | 0.23 | 0.23 | 0.26 | 0.28 | 0.3 | 0.35 | 0.36 | 0.4 | 0.45 | 0.5 | ||

| 3 | Kev kam rau siab tuab | mm | 0.015 | 0.018 | 0.02 | -0.01 | 0.015 | 0.015 | 0.018 | 0.02 | 0.024 | 0.018 | 0.02 | 0.025 | 0.03 | ||

| 4 | PET zaj duab xis thickness | mm | 0.05 | 0.075 | 0.1 | 0.075 | 0.125 | 0.15 | 0.125 | 0.188 | 0.188 | 0.25 | 0.25 | 0.35 | 0.35 | ||

| 5 | Grammage | g/m2 | 165 | 210 | 245 | 255 | 270 | 327 | 330 | 365 | 400 | 445 | 519 | 580 | 640 | ||

| 6 | Lub zog tensile | MD | Tsis tau tais | N/10 hli | 130 | 170 | 210 | 180 | 230 | 158 | 270 | 290 | 223 | 345 | 305 | 420 | 425 |

| Tom qab tais | 130 | 160 | 200 | 180 | 220 | 132 | 270 | 270 | 201 | 335 | 242 | 420 | 425 | ||||

| TD | Tsis tau tais | 100 | 140 | 200 | 150 | 210 | 138 | 240 | 320 | 205 | 380 | 243 | 450 | 455 | |||

| Tom qab tais | 100 | 140 | 200 | 150 | 210 | 123 | 240 | 310 | 173 | 370 | 223 | 450 | 455 | ||||

| 7 | Lub zog tawg | Chav sov. | kV | 8 | 12 | 13 | 12 | 14 | 15 | 14 | 21 | 21 | 22 | 23 | 28 | 29 | |

| 8 | Kev cuam tshuam ntawm cua sov 180 ℃ +/- 2 ℃, 10 feeb | - | Tsis muaj delamination, tsis muaj npuas, tsis muaj nplaum ntws | ||||||||||||||

Ntim Khoom Thiab Khaws Cia

6643 muab rau hauv cov yob, daim ntawv lossis daim kab xev thiab ntim rau hauv cov thawv lossis / thiab pallets

6643 yuav tsum tau khaws cia rau hauv qhov chaw huv si thiab qhuav nrog qhov kub hauv qab 40 ℃. Khaws cia kom deb ntawm hluav taws, cua sov thiab tshav ntuj ncaj qha.

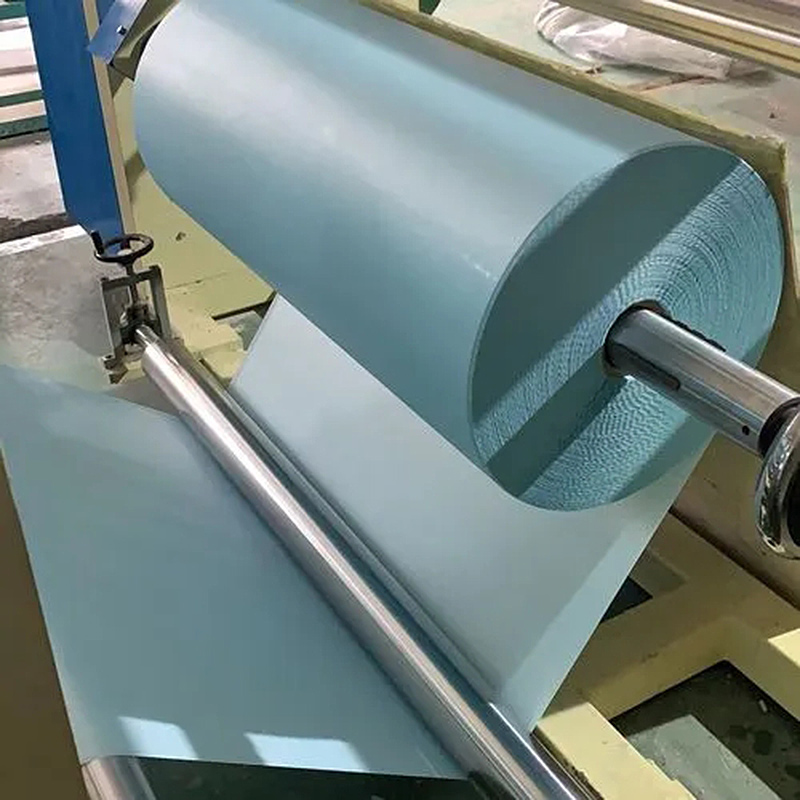

Cov Khoom Siv Tsim Khoom

Peb muaj cov kab rub, lub peev xwm tsim khoom rau kev muaj peev xwm hloov pauv tau yog 200T / hli.